Coating is employed to enhance the properties of the product, such as adhesion, wear and anti-corrosion durability.

At NICA we understand the quality of the product is important to our client’s success and as such we offer a range of coating solutions including roller coating, electrostatic spraying, low pressure air spray, via hole filling, screen printing, customized coating solutions and more.

Our technologies can be adopted for Printed circuit boards, ball grid array, touch panel, LED, IC Substrate, Optoelectronics, automotives, aerospace and semi conductors industries.

Popular option for solder masking. Equipped with latest (butterfly) electrostatic spray gun with max rpm of 5000 and specially designed suspension clamp, fast paced production is ensured.

Along with superior spray coverage as electrostatic spraying technology is suitable for work piece with >0.4mm thickness. This technology also leds to low raw material wastage.

No spray deposition accumulated onto through-hole , no blocked holes after spraying.

Designed to fill holes in substrate with conductive or non conductive paste. And equipped with glass cover for safety and visual quality control, both side of panels can be fill in one cycle.

To ensure quality, the system automatic scavenger system will remove excess plugging paste from the surface of the printed circuit board. Once again, it is equipped with glass cover for safety and visual quality control

At NICA we offer various drying system solutions with different heating source which can be employed for Printed circuit boards, ITO film, touch panel, LED, IC Substrate, Optoelectronics, automotives, aerospace and semi conductors industries. Our drying system has also cooperated with world leading 3C products manufacturer.

We fully understand that each client has its own unique requirements and with our in depth knowledge of the applications and industries, our clients can be assured of turn key and customized coating and drying solutions.

NICA specializes in providing a wide range of industrial ovens to accommodate a variety of applications, including drying, curing, and baking components or final products. Our industrial ovens are available in a full range of standard sizes or specially designed and built to meet specific customer’s requirements. Our industrial ovens include industrial infrared (IR) oven, industrial batch oven, industrial N2 (nitrogen purge) oven, industrial conveyor oven, industrial UV curing oven.

For our valued customers, a comprehensive service which consists of specification, design, installation, and commissioning will be offered for every industrial oven.

| TECHNOLOGIES | ||

|---|---|---|

In our production solutions for this market following technologies are applied: |

||

| Conveyorized Oven | Batch oven | Roll to roll oven |

Widely used in industries including automotive, electronics, substrate manufacturing. In UV curing, there is no solvent to evaporate, no environmental pollutants, no loss of coating thickness, and no loss of volume. With our patented lamps and specially designed reflectors, drying of coatings is achieved instantly with quality uniformity. Our drying system also incorporated energy saving lamp as such half lamp mode is activated depending on client’s time threshold.

Infrared heating, a popular method used by industries due to it’s low heating time required. Down-flow (vertical downward suction) to prevent films from floating or scratched.

Temperature range: 50-600 ℃. Applicable for glass high temperature sintering, glass bake in AR coating process.

Temperature range: AT~ 250℃, Oxygen content:100~50000 ppm (customizable), applicable for baking of PCB without oxidation.

Temperature Range:AT~150℃,Conveying System:Circulating Levitating Rollers. Applicable for Baking of T/P Capacitive Film & RtoR Flexible Electronic Components

Temperature Range:AT~200℃, Conveying System:Levitating Plates. Applicable for Baking of T/P Capacitive Film & RtoR Flexible Electronic Components

Features

(1) Patent Lamp house for excellent UV energy uniformity (up to 90%)

Features

(1) Patent Lamp house for excellent UV energy uniformity (up to 90%)Conveying System Precisive Rollers & Levitating Plates. Applicable for baking of T/P Capacitive Film & RtoR Flexible Electronic Components

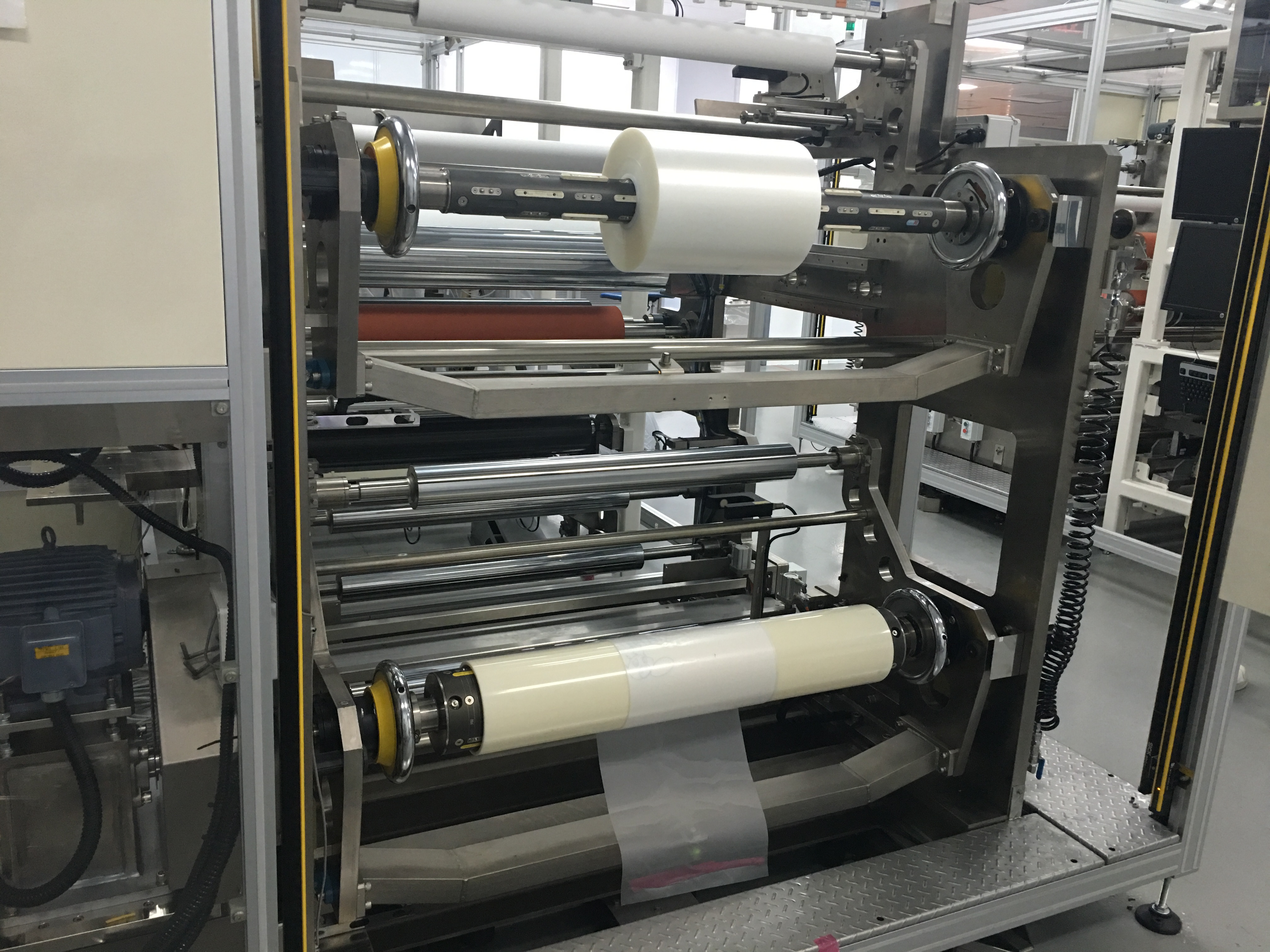

Lamination is employed for image transferring onto a substrate before sending it for subsequent process. The quality of image being transferred will affect the chain of subsequent events.

At NICA we understand the importance of quality image transfer to our client and as such we have a range of laminating solutions to ensure client’s different needs can be fulfilled. It can be use for printed circuit boards, flat panel display, LED, IC substrate, automotive, optoelectronic, aerospace industries.| TECHNOLOGIES | |

|---|---|

In our production solution for this market, we’ve the following technologies to offer |

|

| Cut Sheet Laminator | Vacuum Laminator |

| Roll-To-Roll Slitter | Roll-To-Roll Laminator |

Lamination is employed for image transferring onto a substrate before sending it for subsequent process. The quality of image being transferred will affect the chain of subsequent events.

At NICA we understand the importance of quality image transfer to our client and as such we have a range of laminating solutions to ensure client’s different needs can be fulfilled. It can be use for printed circuit boards, flat panel display, LED, IC substrate, automotive, optoelectronic, aerospace industries.Applicable for printed circuit boards, flat panel display, flip chip

Applicable for printed circuit boards, flat panel display, flip chip

At NICA, we also customise roll-to-roll slitter and roll-to-roll laminator according to customer’s requirements. Our roll-to-roll slitters are designed to accommodate various types of materials, e.g., double-sided tape, masking tape, PET, PE, release liner into several thinner rolls.